Whether you’re an aspiring hobbyist or seasoned professional, there’s currently a tremendous range of choice if you’re looking to purchase a new 3D printer. From simple, compact desktop units to large-scale industrial machines, new printers, technologies and materials are entering the market at a rapid (and increasing!) pace as more and more global companies delve into additive manufacturing. But what exactly is 3D printing?

What is 3D Printing?

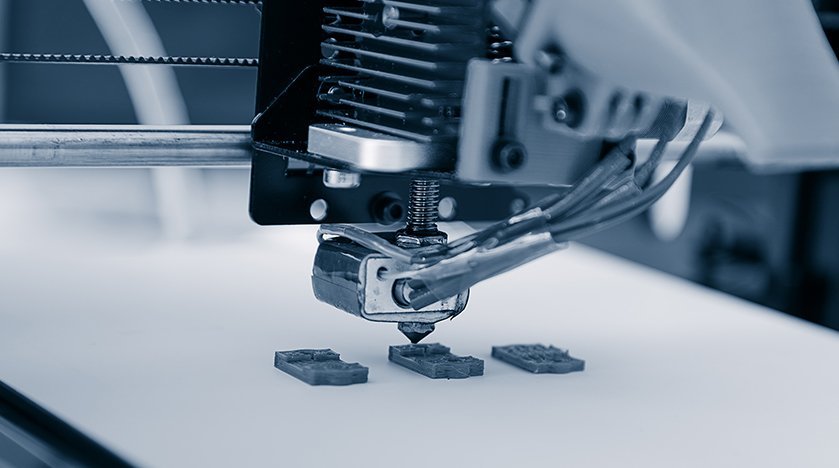

More technically referred to as desktop fabrication or additive manufacturing, 3D printing is basically the process of creating an object layer by layer, in order to create a physical and usable object. This object is generally build using a three-dimensional blueprint.

This process is the exact opposite of the traditional method of creating objects. In the traditional method, raw materials are put through a different mechanical process to finally create the desired object. Here, only technology is required.

There are different technologies used in this process, among which SLS, SLA, FDM and SLM are commonly used. The first technology to be introduced was the SLS technology. An abbreviation for Selective Laser Sintering, SLA was first patented by Carl Deckard and Joe Beaman as part of the DARPA initiative in the 1980s. The two participated in a start-up company called DTM that was later acquired by 3D Systems, owner of a competing technology known as SLA.

SLA (stereolithography), is a term coined and patented in 1986 by Chuck Hull. It was soon commercialized by Mr Hull’s South Carolina based company, 3D Systems. Another commonly used technique is FDM, also known as Fused Deposition Modelling. This technology was introduced by Scott Cramp in 1988 and was patented in 1992 in the United States. FDM was commercialized in the early 1990s by another one of today’s big 3D printing firms, Stratasys. A fourth technology known as Selective Laser Melting was developed in Germany in the 1990s and was commercialized in the early 21st century.

While first being introduced in the 1980s, 3D printing became available to the masses only in the 21st century, more precisely in 2009. A project known as the RepRap Open Source first released affordable 3D printers that could be placed on a desk. To make this possible, they used Fused Deposition Modelling (FDM) technology. In the years thereafter, companies realised the potential in this niche and innovated, created and improved the quality of the consumer 3D printer, also known as the desk 3D printer. Today, these 3D printers are high in quality and affordable, while primarily making use of FDM technology and a few others.

How Does 3D Printing Work?

Simply put, in order to create a 3D printed object, an “additive process” is used, wherein, the three-dimensional object is placed laying down and successive layers of material is applied until the final object is finished.

That being said, the applications of 3D printing are plenty, right from prototyping in a design firm to manufacturing material for engineers. As previously mentioned, there are a couple of commonly used technologies that are used in the 3D printing process. Essentially, all technologies used work towards the same goal; to create the desired object. However, the technique used in each technology differs slightly. The main noticeable difference in each technology is the type of material used and the manner in which it is applied in.

What Materials Are Used In 3D Printing?

FDM:

This technology using a mix of production-grade plastics, like ABS, PLA and Nylon, as well as non-plastic materials like glass, silver, titanium, steel and wax. One of the leading companies in thermoplastic polymer FDM technology, Stratasys, support the following plastics in their process:

- ABSplus

- ABSi

- ABS-M30

- ABS-M30i

- ABS-ESD7

- ASA

- FDM Nylon 12

- PC-ABS

- PC-ISO

- PPSF/PPSU

- ULTEM 908

- ULTEM 1010

Most of these plastics are also commonly used in large-scale manufacturing processes.

SLA:

Stereolithography uses photopolymer resins that change their properties (e.g. harden) based on exposure to light. 3D Systems, a leader in the SLA technology, supports a wide range of custom manufactured materials for its 3D printers. Examples include nylons, epoxy-like materials, rubber-like materials, and thermoplastics.

SLS/SLM:

In the Selective Laser Sintering technology, either a single material or double material powder is used. These materials can include metals like steel or titanium as well as plastics like polystyrene. A composite of various materials like a “green sand” mixture can be used as well.

SEE ALSO: Amazon’s Alexa Economy Facilitates People Building Its Skills

3D printing has still a long way to go. The more we see 3D printing technology that is tailored to specific industrial applications rather than providing ‘one size fits all’ solutions, the faster we will see it establish its ideal niches. All this will help 3D printing reveal itself as a truly mature technology and free itself of the hype and misconceptions that have held it back since its inception.

For more information about the latest technology trends, keep reading iTMunch.

Why Sectors is 3D Printing Most Useful in?

Similar to most of the emerging technologies, 3D printing to offers a lot of benefits in multiple areas. Mentioned below are the key sectors where 3D printing can be used to improve the quality of the products and services offered:

Healthcare

Due to the multiple types of technologies involved, multiple types of materials can be used for 3D printing. This highly benefits the healthcare sector. For example, prosthetic limbs can be products precisely to match the requirements of a patient. Moreover, this can be done at a comparatively lower price, thereby increasing the chances of the lives of millions. This technique is being explored greatly and is named “bio-printing”.

Additionally, 3D printed pens are being commonly used in orthopaedic surgeries, that are more precise, thereby considerably reducing the chances of accidents.

Aerospace

In the aerospace niche, currently, complex parts to build appliances like rockets, take a lot of time to assemble. This not only increases the cost, but also the time taken to explore new aspects of the universe. With the help of 3D printing, these complex parts can be created quickly and at a cheaper price. This not only speeds up the assembly line, but also allows mass production of parts.

Currently, major space agencies, which includes NASA, have been working on creating the perfect shields for shuttles using 3D printing. It won’t be long before 3D printers are used to create satellites in space and are launched directly too.

Manufacturing

Currently, in the manufacturing sector, 3D printing is being used in two ways; rapid prototyping and rapid manufacturing.

Rapid Prototyping

This application has been used for a while now and is extensively used by all types of manufactures. Rapid prototyping, as the name suggests, is a process where brands create prototypes of an upcoming product. Creating a prototype using traditional methods require an investment of thousands of dollars, along with a long wait time for the prototype to be ready. On the other hand, 3D printing created prototypes in a day or two at half of the cost. Moreover, any changes that need to made to the prototype can be done directly on the computer, instead of investing additional labour hours.

Rapid Manufacturing

A fairly new type of application for 3D printing, rapid manufacturing is the perfect example of what 3D printers were created for. Basically, in this process, manufactures directly create products that will be sold to users on the 3D printer. Hence, the object created is not merely a prototype but will actually be used for user consumption.

Product Design

Similar to manufacturing, 3D printers are extensively used for prototyping in the product designing niche. However, the concept of manufacturing products that can be directly sold to the end-consumer is quickly catching up. In fact, this concept has already been introduced for products like furniture, lighting, décor items, jewellery and accessories.

SEE ALSO: MOREbot Uses 3D Printed Parts to Introduce Robotics to Children

Auto Industry

Probably one of the first industries to commercially use 3D printing, the auto industry makes use of 3D printing techniques for building parts as well as interior elements and tools. The biggest benefit of using 3D printing in this sector is the possibility of increased on-site development and reduced reliability on importing manufacturing unites to a large extent.

A very good example of optimal use of 3D printing in the auto industry is Audi. This car company uses technology to create metal spare parts. This allowed the auto giant to disrupt a long supply chain, and create parts using the metal printer, only when required.

Aviation

Right up there with the Auto industry, Aviation to has been making use of 3D printing for a while. In today’s date, this niche heavily depends on this technology for carrying out its activates. A prime example of 3D printing in aviation is Boeing, the leading name in aviation manufacturing. According to reports released by the company, in 2015, Boeing used more than 20,000 3D printed parts for their aeroplanes. For instance, the Boeing 787 used 3D printed titanium. The use of this material in one single aircraft alone saved the manufacturer around 2-3 million dollars.

Another company in the Aviation sector that has used 3D printing effectively is Airbus. This company created frames and shapes with improved design and materials. The aim is to create lighter aircraft, thereby improving the aerodynamics of the vehicle. According to Airbus, by using 3D printing for creating the parts they require, they allow designers more time to focus on improving the functionality and design of the product using aeroplane engineering.

Construction

Yes, soon, we will be living in print buildings! There are a couple of companies like Apis Cor, who are already working with 3D printing in the construction niche. Apis Cor claims to be able to print a house in less than 24 hours. Similarly, WuSun, a Shanghai-based entity, is currently printing hours using recyclable materials at $4,800 per unit. Basically, parts of the house are created and put together to create the entire livable building. While these concepts have still not evolved in the mainstream market, they have made rapid progress.

Food

As unlikely as it may sound, the usage of 3D printing in the food industry is not new. Restaurants like Melisse and Food Ink have been making use of this technology to create food items that are unique and have proven to be a customer favourite. There are certain reports that suggest that even NASA might be considering printing pizzas in space.

If this goes on, it won’t be long before the food industry is dominated by shape-changing pasta or candies popping out a 3D printer, instead of a vending machine.

Fashion

This is one industry that can leverage the complete potential of 3D technology. Designers have been using this technology for a while now in order to streamline products and retail systems. But, recently, the use of 3D printers in the fashion niche has increased tenfold. Fashion designers are giving their customers the option to download and print their collections. For example, Designer Danit Peleg has integrated a 3D printing model on her website, using which customers can customize the type of jacket they want, which is then printed at any 3D printing facility. Another example is Iris Van Herpen, who has brought 3D printing to the haute couture culture. She is known to print her entire line of clothing in collaboration with Materialize. Giants like Adidas to have been mass-producing sneakers for their customers using 3D printing.

SEE ALSO: Make Your Own Clothes Using This AI-Based Knitting Design Software

That being said, even though 3D printing is already deeply implemented in the world of prototyping, it still quite a few years away from actually being introduced to the mainstream world. This is due to the relatively long duration required to print something. Arguments stating that the same or probably lesser time is needed to create objects in the traditional way. However, as technology advanced and new upgrades are made to 3D printers, this problem too will have a solution. After all, being the cutting-edge technology that it is, 3D printing is sure to change the world as we know it!

For more latest updates, tips and news about the tech world, including IT, Marketing, Finance, Startups and HR, keep reading iTMunch.